> Optical analysis has become the cleanliness industry standard analysis, with economic, rapid detection, easy to operate characteristics;

> The VDA19 standard analysis particle is more than 50um, which can no longer meet the needs of industry development;

> Optical analysis can detect particle type, classification, number of intervals, maximum particle and so on.

> Optical analysis can detect the size information of pollutant particles, such as length, width, area, tangent circle and height.

> The metal particle identification accuracy can reflect the superior performance of an analysis system;

> Metal particles: are usually the most concerned and are the most critical particles.

> Non-metallic particles, without fiber: These particles are critical pollutant particles like metal particles.

> Fibers: These particles cannot be avoided during the preparation and operation of the test. Therefore, even if the fiber is sometimes the largest particle on the filter membrane, its attention is relatively low。

> But there is also a risk that too much fiber will cause some parts to fail.

Particle interval classification and standard grade [VDA19/ISO16232]

Table 1:

| Size Class | Size x [um] |

| B | 5≤ X <15 |

| C | 15≤ X <25 |

| D | 25≤ X <50 |

| E | 50≤ X <100 |

| F | 100≤ X <150 |

| G | 150≤ X <200 |

| H | 200≤ X <400 |

| I | 400≤ X <600 |

| J | 600≤ X <1000 |

| K | 1000≤ X |

Table 2:

| Number of particles per 1000 cm2 or per 100 cm3 | Cleanliness level | |

| More than | Up to and including | |

| 0 | 0 | 00 |

| 0 | 1 | 0 |

| 1 | 2 | 1 |

| 2 | 4 | 2 |

| 4 | 8 | 3 |

| 8 | 16 | 4 |

| 16 | 32 | 5 |

| 32 | 64 | 6 |

| 64 | 130 | 7 |

| 130 | 250 | 8 |

| 250 | 500 | 9 |

| 500 | 1x103 | 10 |

| 1x103 | 2x103 | 11 |

| 2x103 | 4x103 | 12 |

| 4x103 | 8x103 | 13 |

| 8x103 | 16x103 | 14 |

| 16x103 | 32x103 | 15 |

| 32x103 | 64x103 | 16 |

| 64x103 | 130x103 | 17 |

| 130x103 | 250x103 | 18 |

| 250x103 | 500x103 | 19 |

| 500x103 | 1x103 | 20 |

| 1x103 | 2x103 | 21 |

| 2x103 | 4x103 | 22 |

| 4x103 | 8x103 | 23 |

| 8x103 | 16x103 | 24 |

Table 1. Particle size grades in standard ISO 16232:2007 Part 10. Table 2. Particle cleanliness grades in standard ISO 16232:2007 Part 10.

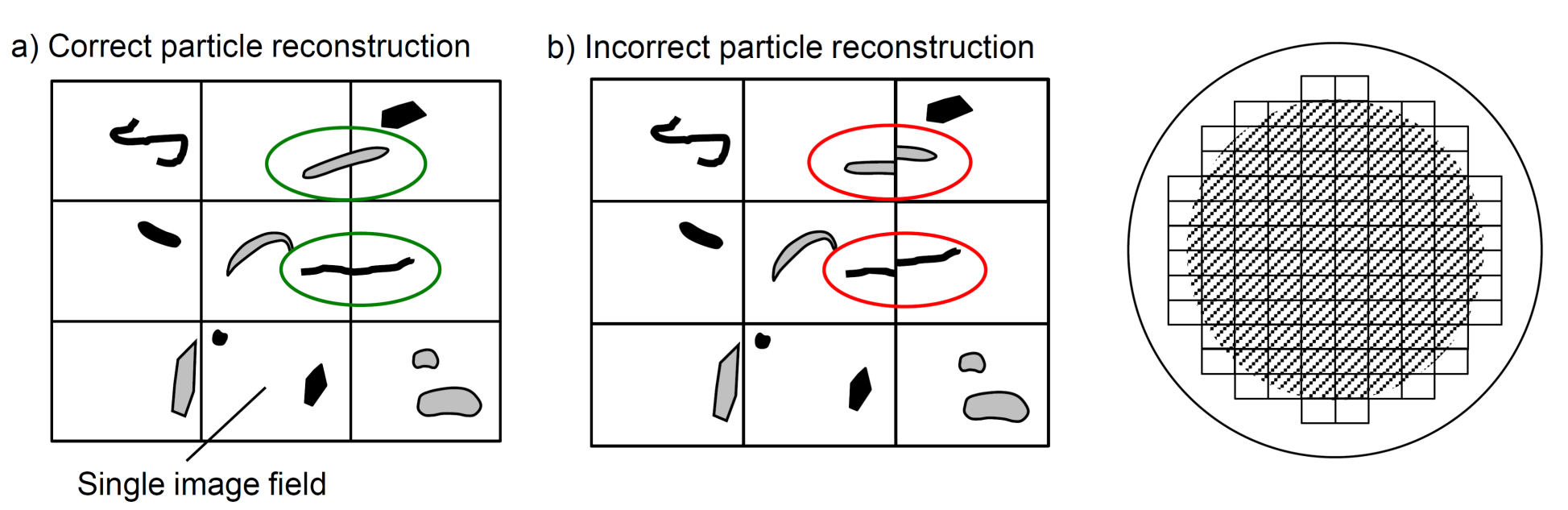

The 47/50mm standard filter membrane was scanned step by step and seamlessly splicing. After splicing, the whole filter membrane was analyzed for particles, and the particles were sorted.

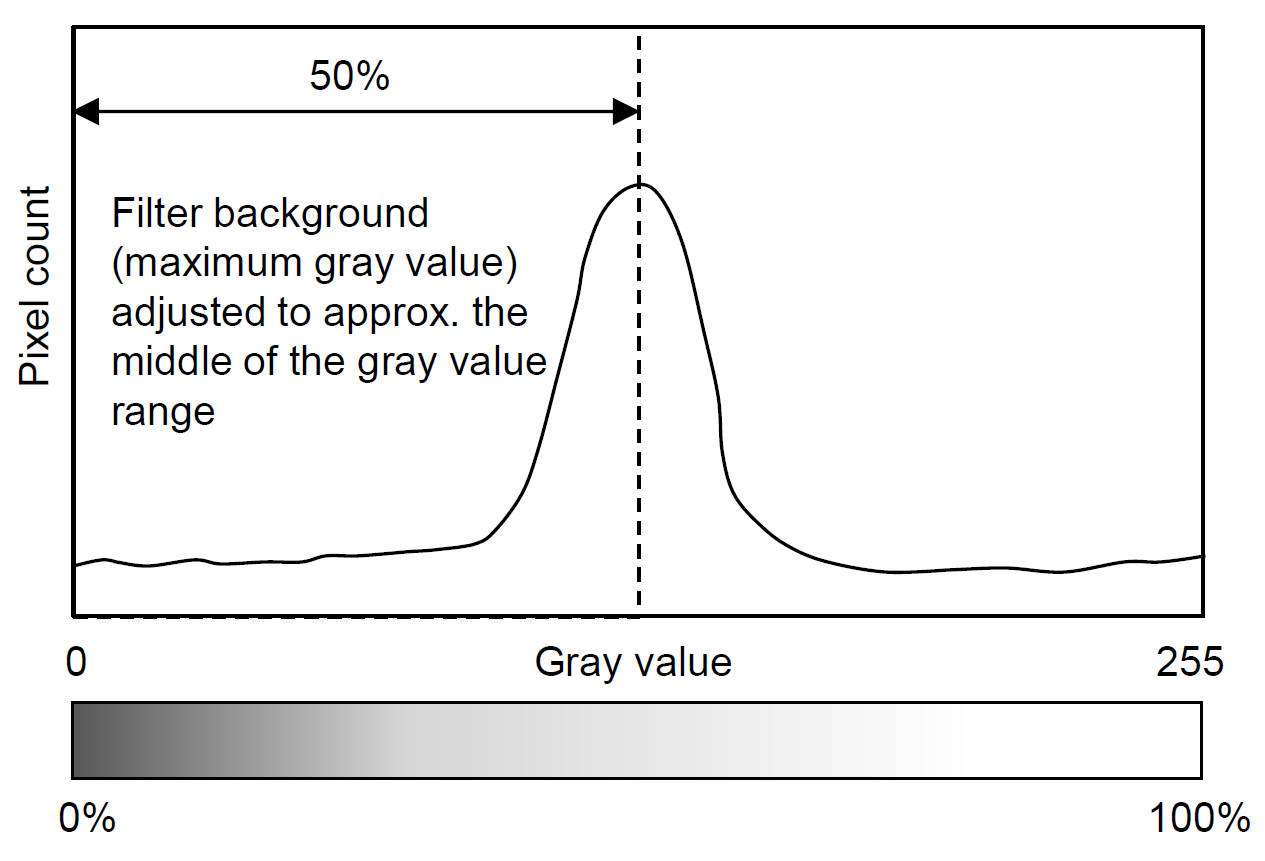

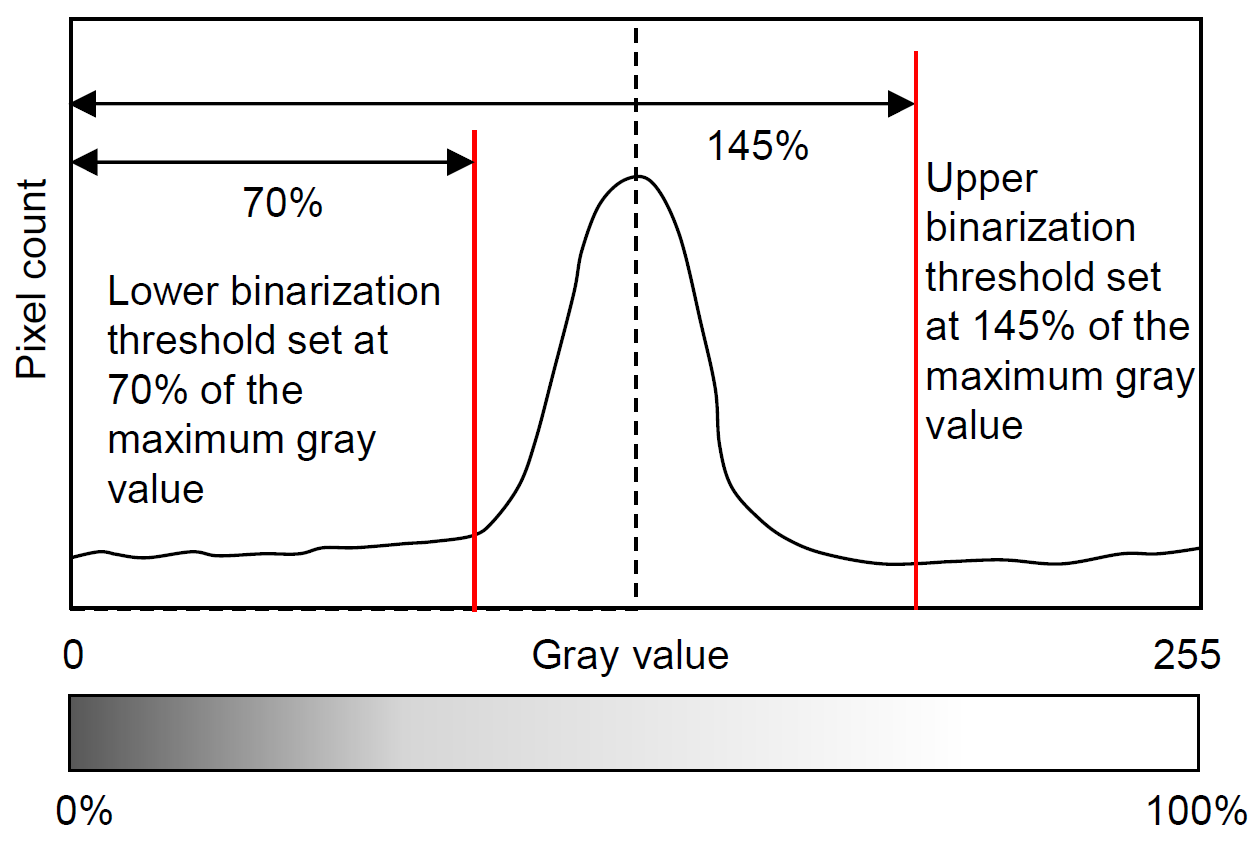

> The whole brightness area is divided from black to white according to the gray value level. A total of 0-255 grayscale levels were created for particle analysis.

> Image processing software uses thresholds to determine which regions belong to the particle and which belong to the filter background (quadratic threshold);

> When optical particle analysis is performed with a microscope, data can only be acquired for particle structures smaller than the binary threshold (darker than the filter background).

Non-metal - metal recognition principle

| Particle type | Parallel polarized light mode | Cross polarized light |

| A: Metal particles |  |

|

| B: Non-metallic particles |  |

|

| Metal particles in two lighting modes: Bright field [using parallel polarizers] : Freely moving electrons in the metal produce reflected light, and metal particles are bright. Polarized light [using cross-aligned polarizers] : Inhibit polarized light reflection, metal particles are dark Non-metal, glass, fiber, plastic, abrasive and other materials do not have this property. Compare two images (contrast of two polarizers in parallel and cross state) Polarized light is the key to metal-non-metal identification, and the coating process of polarized lens directly affects the accuracy of particle detection The ID position of the two images must be the same, otherwise there will be misjudgment of metal particles |

||

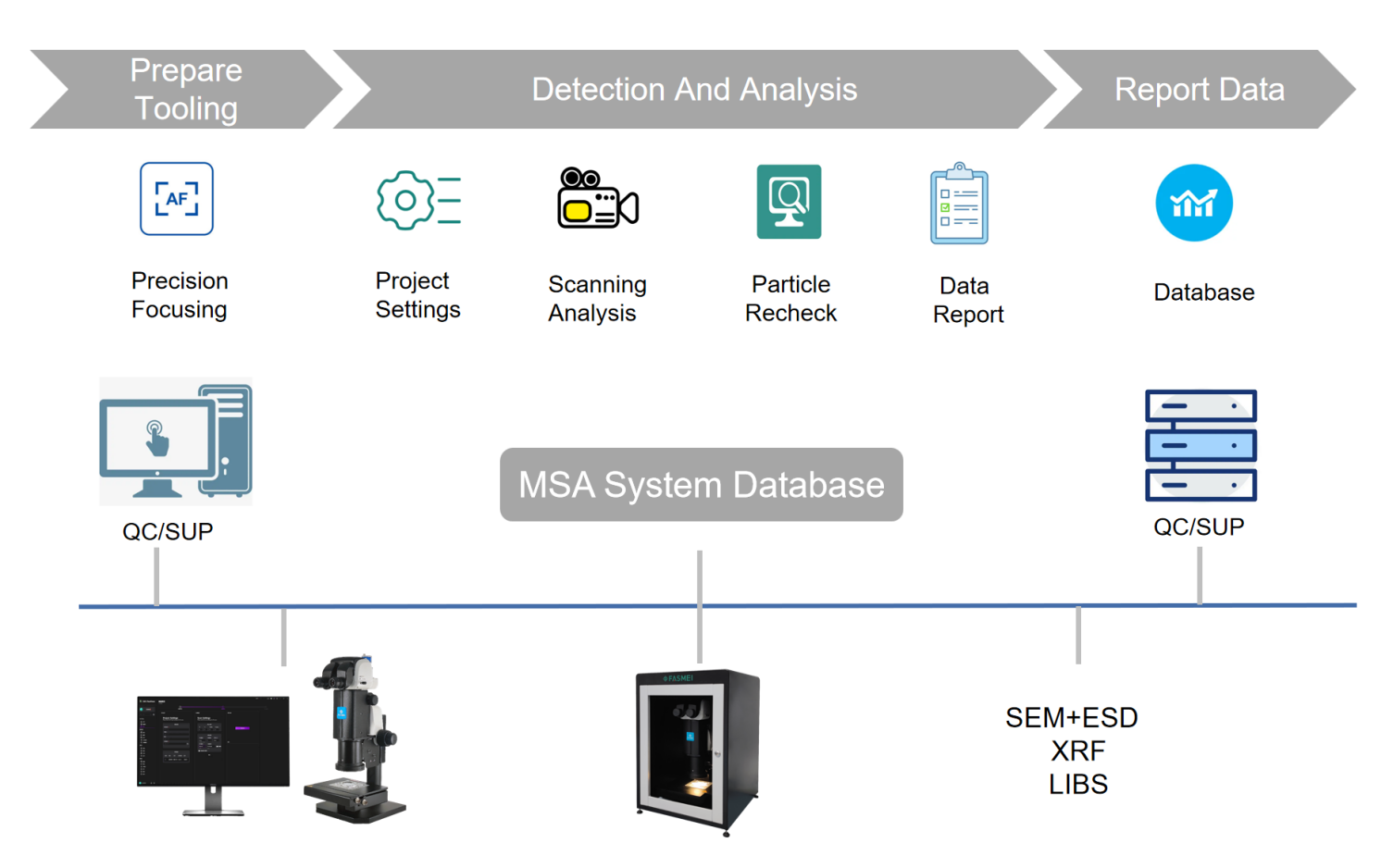

> The FASMEI cleanliness measurement and analysis process is extremely simple and can be easily mastered by inexperienced operators in less than half an hour.

> FASMEI cleanliness measurement system design from the beginning of the development of the requirements of the operation process must be simple, automated, accurate, data, standardized.

> FASMEI series measurement system does not need to manually adjust the light source, polarized light, automatic scanning analysis.

> Database guarantees traceability, MSA system database.

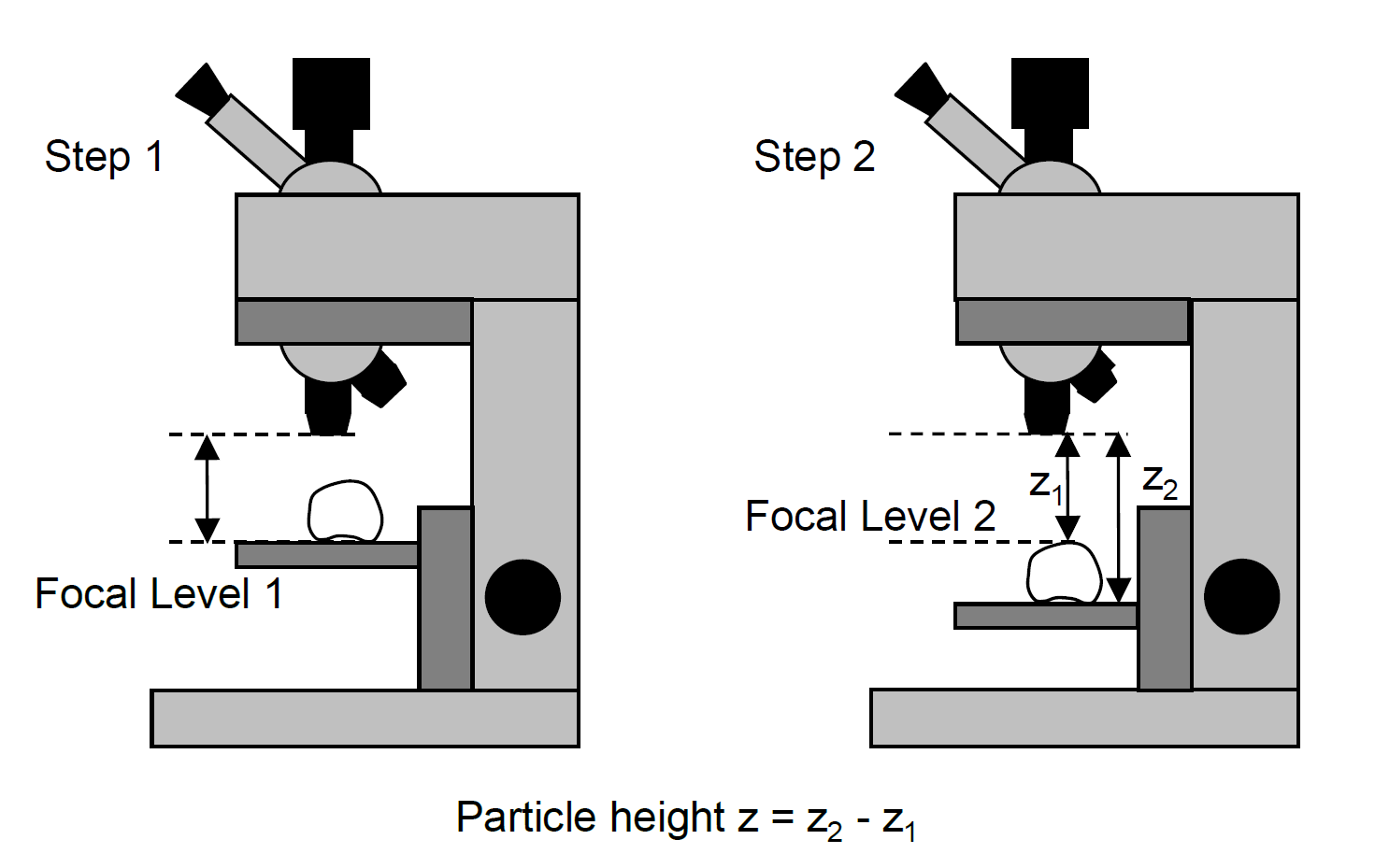

Particle height measurement

In some high-demand components, such as fluid hydraulic components, it is not enough to measure the length and width of the particle, and it is often necessary to measure the particle height information. The measurement method is as follows

Particle property

For example, the extended particle analysis technique described in the VDA-19 standard. Automatic scanning electron microscopes with SEM-EDX are widely used in cleanliness laboratories around the world.