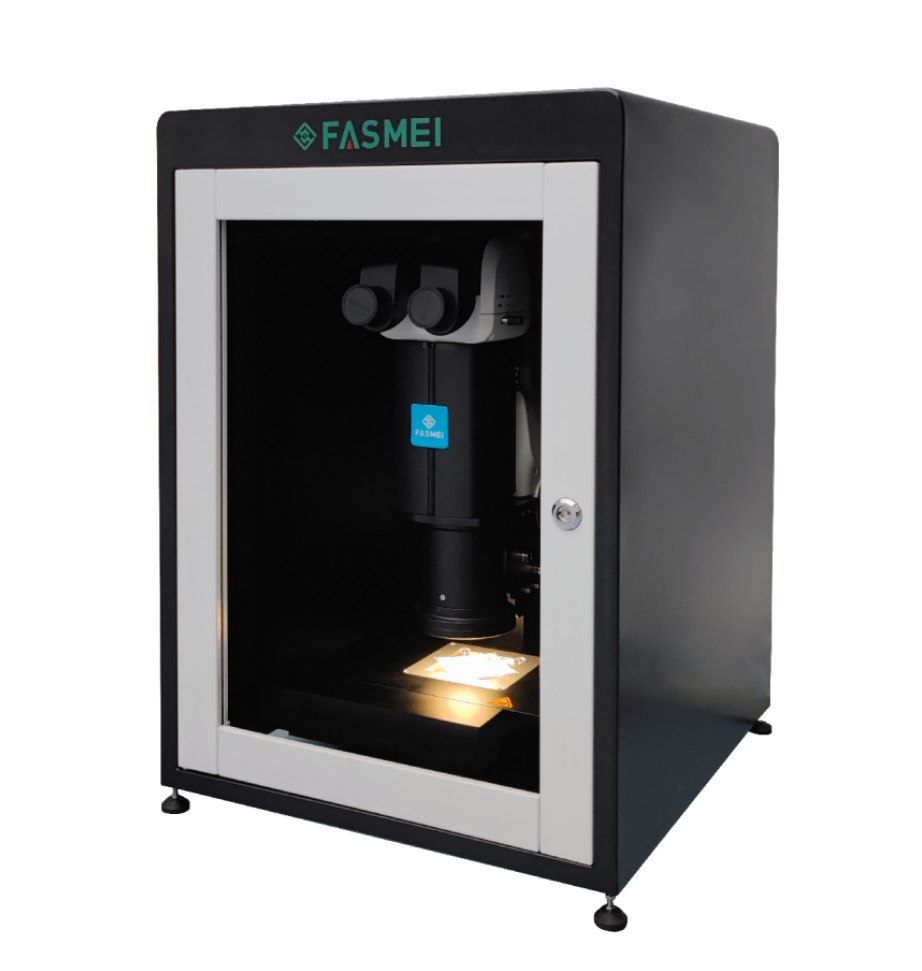

FASMEI 910 New generation of intelligent cleanliness particle analysis system, a new analysis model, redefines cleanliness particle analysis;

International first-class hardware configuration, detection speed to achieve a revolutionary leap;

Scanning time<3min;

The analysis process is fully automated;

One-key analysis of metallic nonmetallic fiber particles;

Automatic polarized light, automatic rate recognition;

software adopts intelligent algorithm, image stitching is better, particle recognition is more accurate ;

Strict implementation of ISO16232/VDA19.1 and other international cleanliness analysis standards;

The system's maximum original color of reduced particle pollutants and the accuracy of particle data measurement;

Superior software performance, easy to use, free upgrade;

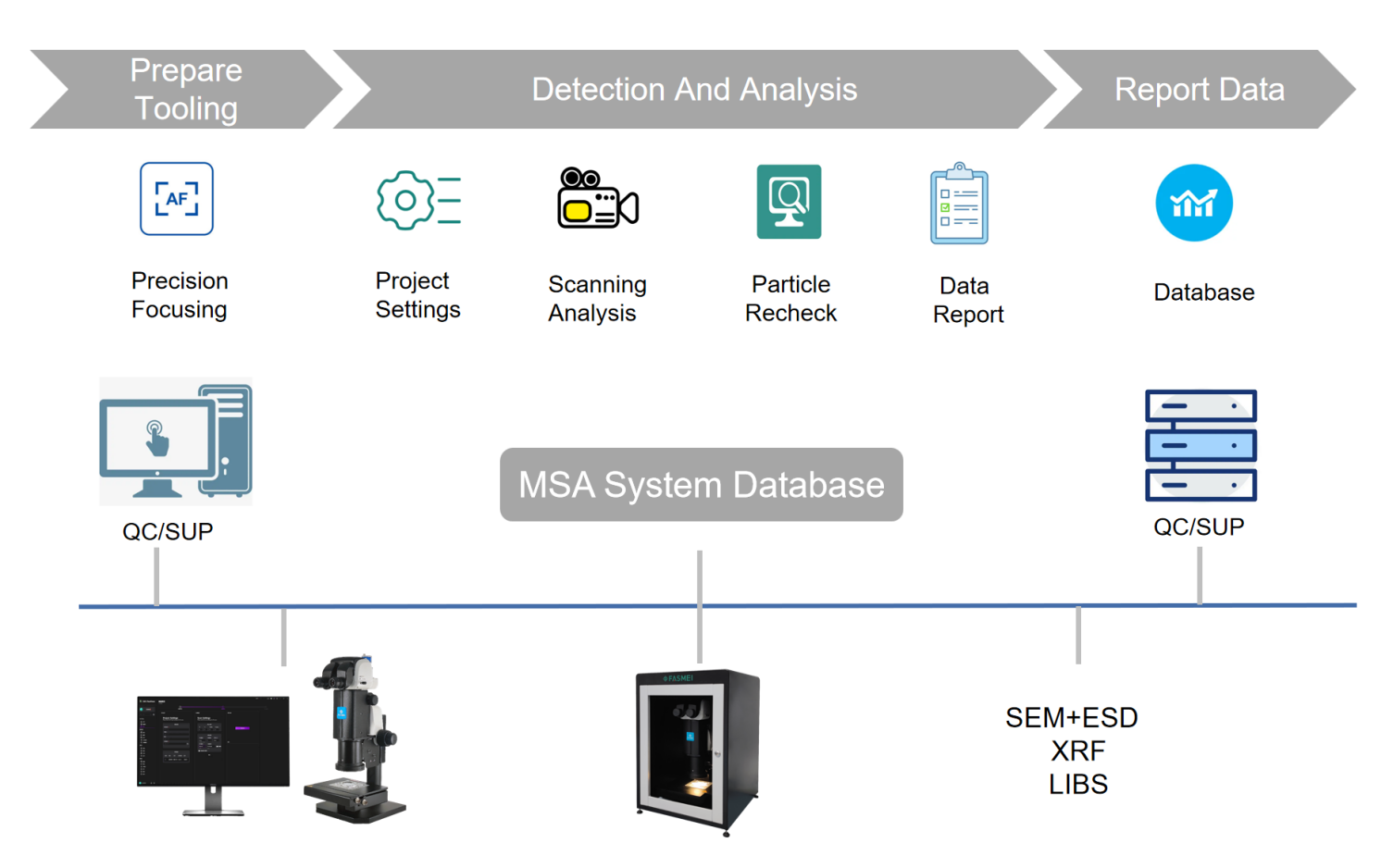

Analysis results MAP map storage, data storage specified root directory, can be arbitrarily invoked and new analysis;

SQL database statistics, can be arbitrarily called historical data (maximum metal particles, particle number, etc.), and expressed in trend charts, to provide data support for product process improvement.

18: 1 Large magnification ratio

Detection particles ≥5um

Automatic light source

Automatic polarized light

Power automatic setting

Fully automated analysis process

One-click scanning analysis of metal, non-metal and fiber particles

MAP Full map preview

Any granular browse

With SQL analysis statistical database

Automatic scanning, seamless jigsaw technology

One-click scanning analysis, A key report

Built-in ISO16232 / VDA19 / CATL/ISO4406 cleanliness testing standard

User customizable analysis standard

Software supports a variety of standard analysis current

Tell a particle type automatic detection (metal, nonmetal, fiber)

Evaluation parameters (length, width, area, maximum fiber length)

Calculate workpiece cleanliness code (CCC) according to standard ISO 16232 /VDA19

Effective particle handling (e.g. overlapping particles), scan results can be manually modified

Particles of any shape can be divided or correlated

Each particle can be positioned to look back

RSD≤2%

Particle calibration≤2pixle

18:1 Large zoom ratio optical host

Long depth of field apochromatic system

Scanning time < 3min

High reducibility color camera, SONY chip

Ultra-high precision automatic scanning table Automatic polarization LED light source

Self-correcting particle standard block

One-key scanning analysis of metal, non-metal, fiber particles

MAP of analysis results storage, data storage specified root directory, can be arbitrarily called and re-analyzed

Configuration of filter clamp special bracket, Compatible with standard filter clips and filter film

software intelligent algorithm, to achieve a real sense of seamless image stitching

Membrane filter slide: 50/47 mm general filter membrane, membrane filter can be permanent test test membrane filter:

0.45um / 0.8 um / 5 um / 10 um /20 um / 40um / 100 um

fallout testing membrane: laboratory, workshop dust fall test

fallout test frame: SUS304

Instrument dust box