FASMEI Lithium electromagnetic particle Cleanliness Analyzer - faster and more accurate

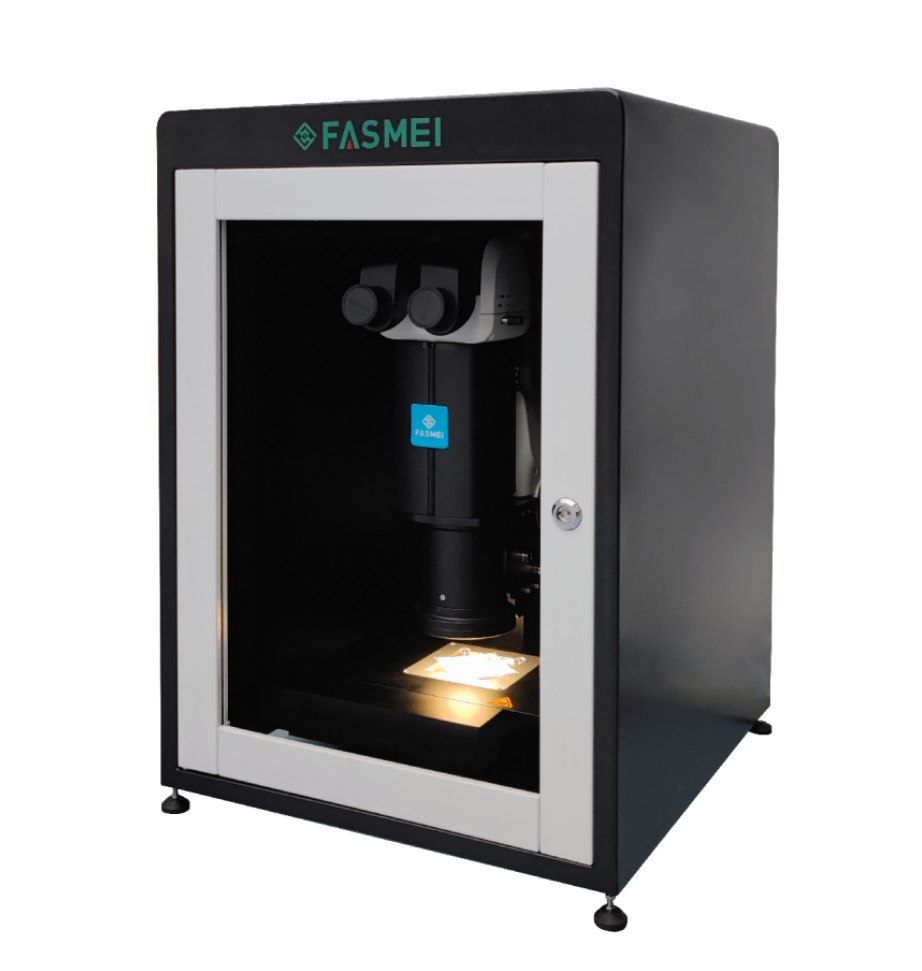

FASMEIMagnetic particle cleanliness analyzer

In the process of manufacturing lithium batteries, magnetic metal impurities will inevitably produce, these magnetic metal impurities will not only affect the self-discharge performance of lithium battery materials, reduce the specific capacity and energy density of lithium battery materials, but also dissolve in the electrolyte a series of side reactions, affecting the service life and safety performance of lithium batteries.

How to accurately and quickly detect the quantity and size of metal particles in raw materials is very important.

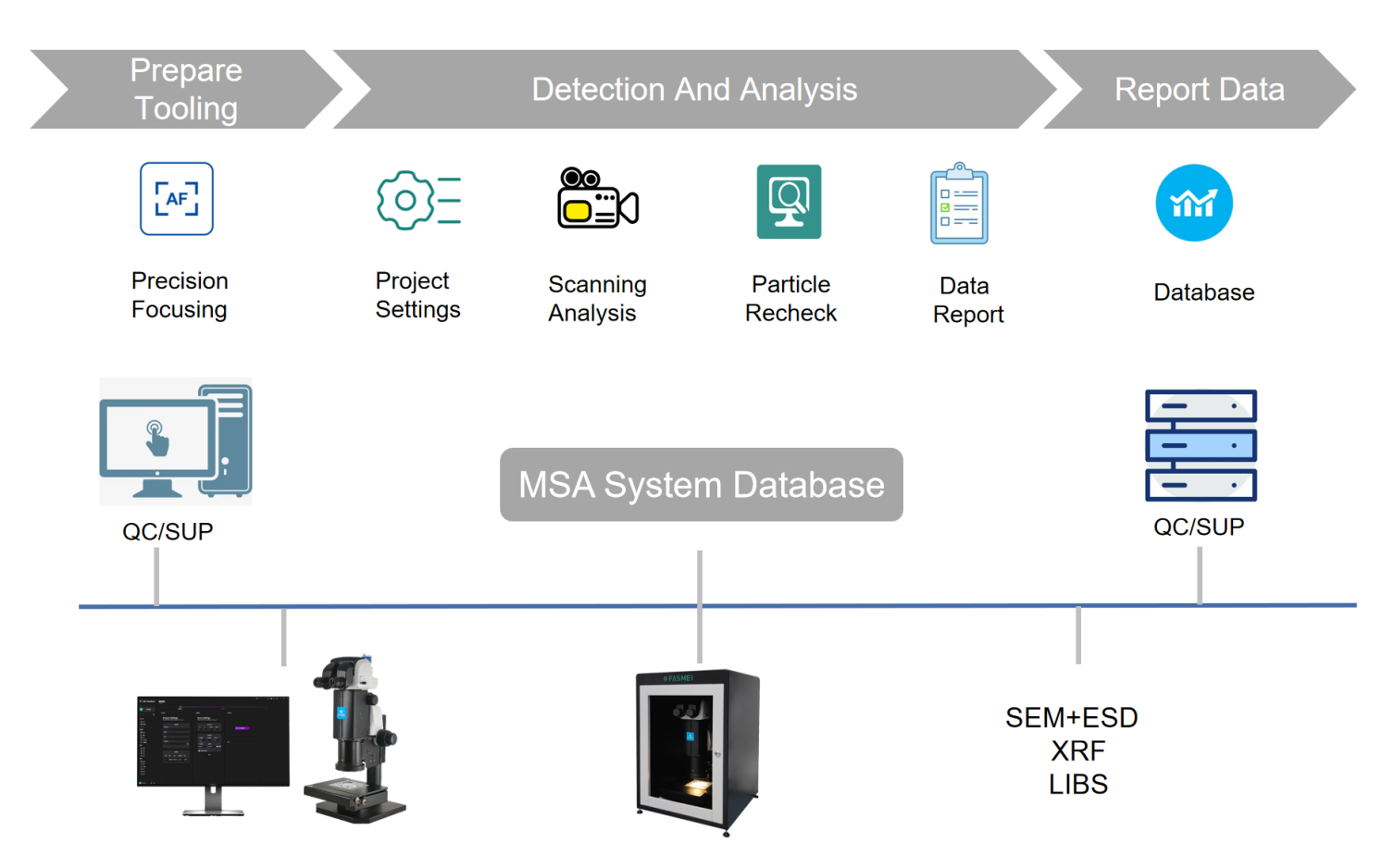

FASMEI magnetic particle cleanliness analyzer improves the metal particle recognition rate by 20-30% compared to traditional equipment, and the detection speed is faster.

Built-in SQL powerful database statistical analysis function to provide granular data comparison for different production processes.

Applications:

Positive electrode material

Negative electrode material

Electrolyte

Diaphragm

sizing

In the process of manufacturing lithium batteries, magnetic metal impurities will inevitably produce, these magnetic metal impurities will not only affect the self-discharge performance of lithium battery materials, reduce the specific capacity and energy density of lithium battery materials, but also dissolve in the electrolyte a series of side reactions, affecting the service life and safety performance of lithium batteries.

How to accurately and quickly detect the quantity and size of metal particles in raw materials is very important.

FASMEI magnetic particle cleanliness analyzer improves the metal particle recognition rate by 20-30% compared to traditional equipment, and the detection speed is faster.

Built-in SQL powerful database statistical analysis function to provide granular data comparison for different production processes.

Applications:

Positive electrode material

Negative electrode material

Electrolyte

Diaphragm

sizing

Technical parameter

Detection particles ≥5um

18:1 Large variable ratio optical host

Long depth of field apochromatic system, scanning analysis time<3min

High reducing color camera, SONY chip, ultra-high precision automatic scanning table

Automatic polarization LED light source, automatic magnification, system particle standard block

Built-in ISO16232/VDA19/CATL and other international cleanliness standards

One-key scanning analysis of metal, non-metal, fiber particles

Analysis results MAP map storage, data storage specified root directory, can be arbitrarily called and re-analysis

Equipped with special bracket for filter clips, compatible with standard filter clips and filter film

Large scale scanning, multi-station scanning expansion, photoelectric joint expansion

SQL database statistics, can be arbitrarily called historical data (maximum metal particles, particle number, etc.), and expressed in trend charts, to provide data support for product process improvement.

18:1 Large variable ratio optical host

Long depth of field apochromatic system, scanning analysis time<3min

High reducing color camera, SONY chip, ultra-high precision automatic scanning table

Automatic polarization LED light source, automatic magnification, system particle standard block

Built-in ISO16232/VDA19/CATL and other international cleanliness standards

One-key scanning analysis of metal, non-metal, fiber particles

Analysis results MAP map storage, data storage specified root directory, can be arbitrarily called and re-analysis

Equipped with special bracket for filter clips, compatible with standard filter clips and filter film

Large scale scanning, multi-station scanning expansion, photoelectric joint expansion

SQL database statistics, can be arbitrarily called historical data (maximum metal particles, particle number, etc.), and expressed in trend charts, to provide data support for product process improvement.

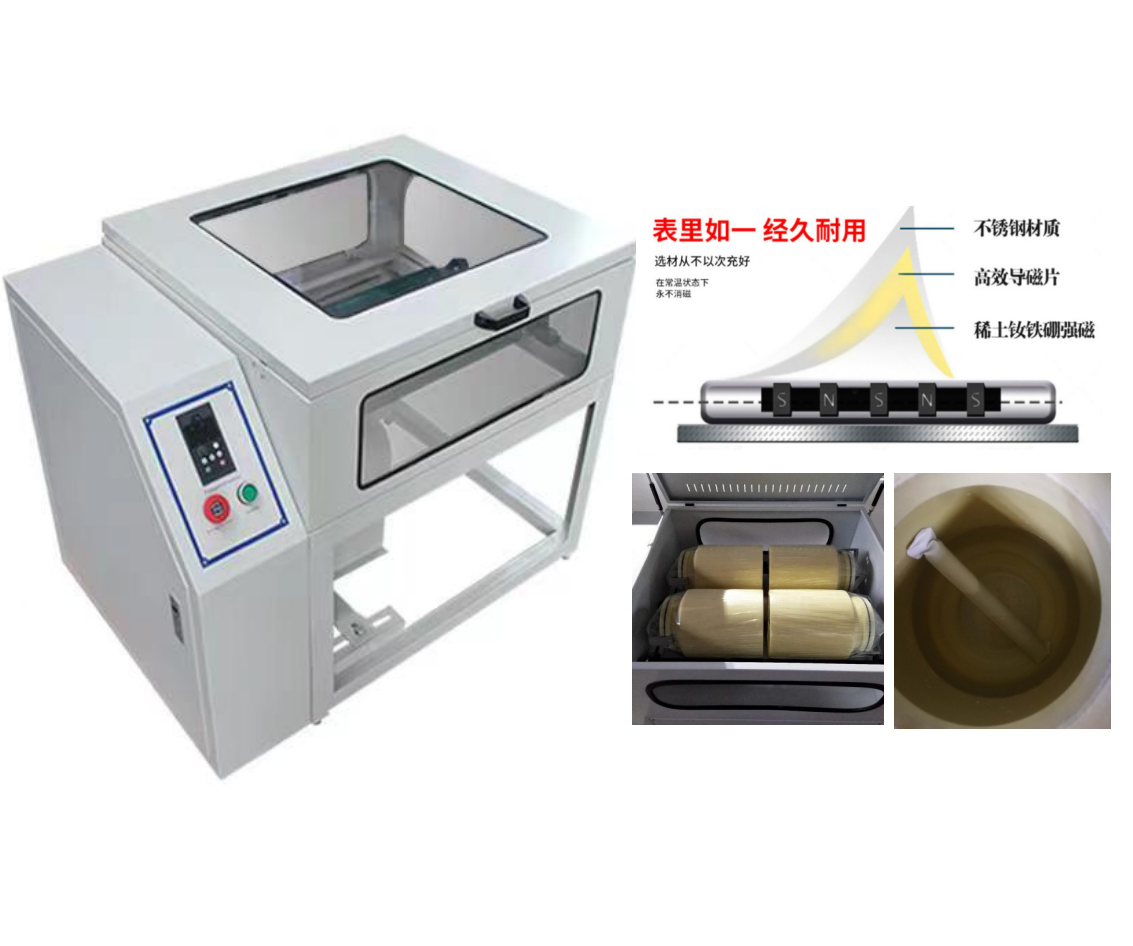

Lithium electric magnetic particle sample preparation equipment

Preparation principle:

The magnetizable metal foreign body in the powder will be adsorbed on the magnetic rod, and the magnetic rod will be used for extraction many times. The substance adsorbed on the magnetic rod will be washed into the beaker, and the material will be repeatedly cleaned and removed. The magnetizable metal foreign body obtained will be pumped, filtered, dried and made into film.

Features:

1. Multiple rollers can be prepared at the same time;

2, can be intermittent or continuous operation;

3, according to the requirements for timing speed regulation;

4, suitable for raw materials uniform speed mixing, high efficiency;

5, wear-resistant nylon mixing bucket

6, the bearing roller is made of special materials, durable

7, 12000GS magnetic bar and auxiliary magnetic block

8, high power fast sealing machine 9, negative pressure vacuum filtration system

The magnetizable metal foreign body in the powder will be adsorbed on the magnetic rod, and the magnetic rod will be used for extraction many times. The substance adsorbed on the magnetic rod will be washed into the beaker, and the material will be repeatedly cleaned and removed. The magnetizable metal foreign body obtained will be pumped, filtered, dried and made into film.

Features:

1. Multiple rollers can be prepared at the same time;

2, can be intermittent or continuous operation;

3, according to the requirements for timing speed regulation;

4, suitable for raw materials uniform speed mixing, high efficiency;

5, wear-resistant nylon mixing bucket

6, the bearing roller is made of special materials, durable

7, 12000GS magnetic bar and auxiliary magnetic block

8, high power fast sealing machine 9, negative pressure vacuum filtration system