The meaning of cleanliness is very wide, it can indicate the cleanliness of parts or products, it can also indicate the cleanliness of raw materials, or the degree of contamination of parts, assemblies and specific parts of the whole machine, and the quality, size and quantity of impurity particles collected from the specified characteristic parts or raw materials are expressed by the general prescribed method. The particles in the cleanliness test are generally divided into three types: metal, non-metal and fiber.

Cleanliness test standards:

1、VDA19

The cleanliness of parts originated in 1996, and in 2015, the German Automotive Industry Association published the latest VDA 19-2015 standard, which has become the cleanliness industry framework standard and also the blueprint for the cleanliness testing standard of the international standard ISO 16232. The 2018 version of ISO 16232 has been developed to be fully compatible with the VDA 19 standard.

2、ISO16232

In 2005, the non-governmental organization ISO (International Organization for Standardization) developed the cleanliness standard ISO 16232 - Cleanliness of Road vehicles - Fluid circuit components, Parts 1 to 10, establishing extraction and analysis methods.

ISO16232 includes the following parts:

- Part 1: Vocabulary

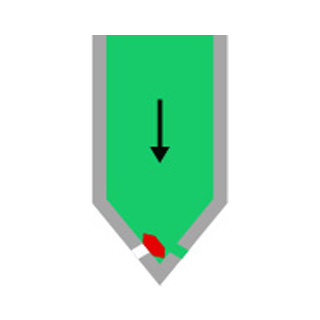

- Part 2: Methods of stirring to extract contaminants

- Part 3: Methods for extracting contaminants by pressure flushing

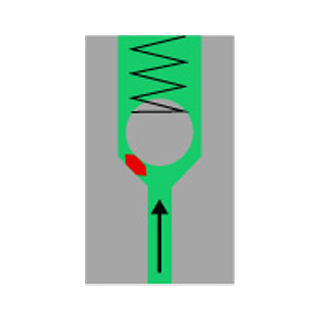

- Part 4: Methods for extraction of contaminants by ultrasonic technology

- Part 5: Methods for extracting contaminants from multifunctional test benches

- Part 6: Determination of particle mass by gravimetric analysis

- Part 7: Microscopic analysis for particle size determination and counting

- Part 8: Determination of particle properties by microscopic analysis

- Part 9: Automatic extinction particle counters for particle sizes and counts

- Part 10: Presentation of results

ISO 16232-2018 is the latest cleanliness test standard.

3, fluid hydraulic and aviation cleanliness standards

ISO4406 Hydraulic fluid power — Fluids — Method for coding the level of contamination by solid particles

ISO4407 Hydraulic fluid power — Fluid contamination — Determination of particulate contamination by the counting method using an optical microscope

ISO18413 Hydraulic fluid power — Cleanliness of components — Inspection document and principles related to contaminant extraction and analysis, and data reporting

NAS1638 Cleanliness Requirements of Parts Used in Hydraulic Systems

The importance of cleanliness control has nothing to do with:

Product reliability Product safety Product durability Environmental protection and energy saving

Cleanliness is very important for many products

In many industries, products can result in quality defects due to direct contact with critical particles

ISO 16232 and VDA19.1 cleanliness standards have become the mainstream cleanliness analysis standards in the industry.

In the lithium industry cleanliness testing standards and specifications are more demanding.

Failure example:

-

Lithium battery

Positive and negative electrode materials

Positive and negative electrode materials

Sizing material

Diaphragm

Electrolyte Electrolyte -

The bearing or sliding surface is stuck

Turbocharger

Turbocharger

Crankshaft bearing

Metering pump

Cylinder face -

The valve is stuck

ABS、ESP

ABS、ESP

Hydraulic unit

Brake booster -

Clogged nozzle or filter

Oil injector

Oil injector

Fuel supply -

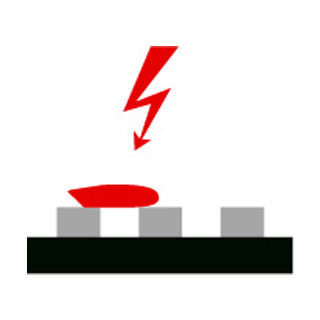

Conductor short circuit

Control electronics

Control electronics

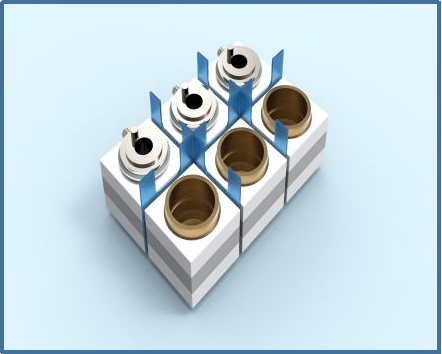

- Cleanliness Extraction equipment

- Cleanliness Analysis System

- Electronic Precision balance

- Natural convection drying oven

- SEM/EDS

- Rapid dryer

- Drying dish (desiccant)

- Weighing dish

- Filter membrane

- Tweezers

- Cleaning solution

- Dust-free cloth

- Corrosion resistant gloves

- Clean clothes

- Safety cabinet

- Balance table

- Protective glasses

- Protective mask

- Deelectrometer

What factors affect cleanliness test results:

Blank value

Cleaning parameters

Analysis system

Operator level

Environmental factors, etc

Essential elements for qualified cleanliness testers:

Necessary training

Importance of cleanliness

Principle of metal particle recognition

Awareness of blank values

Basic knowledge of microscopy

Basic knowledge of cleanliness theory

| Test preparation : Job preparation Confirmed quantity Condition confirmation Cleaning work Filter membrane drying and weighing M1 |

|

| Blank test : OK, proceed to the next step Standard: Pollutant quantity 10% Pollutant weight 10% Maximum particle 1/2, lower limit |

|

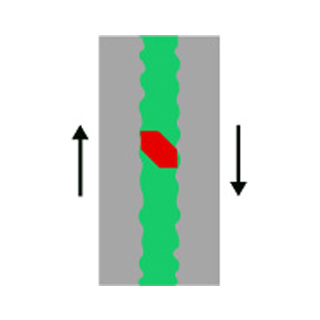

| Parts cleaning extraction : Parameter: Decrement test parameter Particle collection: Liquid recovery onto standard diaphragm Spray pen cleaning is recommended Necessary rinsing procedures Minimize atomization Necessary exhaust measures |

|

| Filter membrane weighing : Drying balance weighing M2 MG=M2-M1 Necessary constant weight test work Balance accuracy Avoid particle loss Antistatic measures |

|

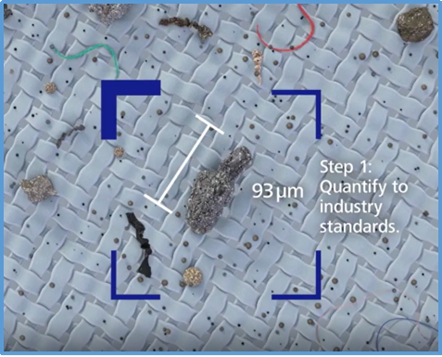

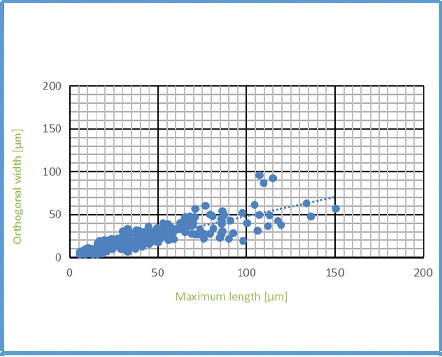

| Particle analysis : Cleanliness is measured by analyzing the filter membrane, which contains residue particles cleaned from the surface of the product Necessary automated light source Standard threshold Automatic image Mosaic Metal non-metallic fiber particles are differentiated |

|

| Particle review : Particle location Metal particle recognition principle Particle splitting and joining Property modification Fiber particle |

|

| Data Report : Reporting Specifications Job Information Extract information Particle image Data accuracy Database backup |

|