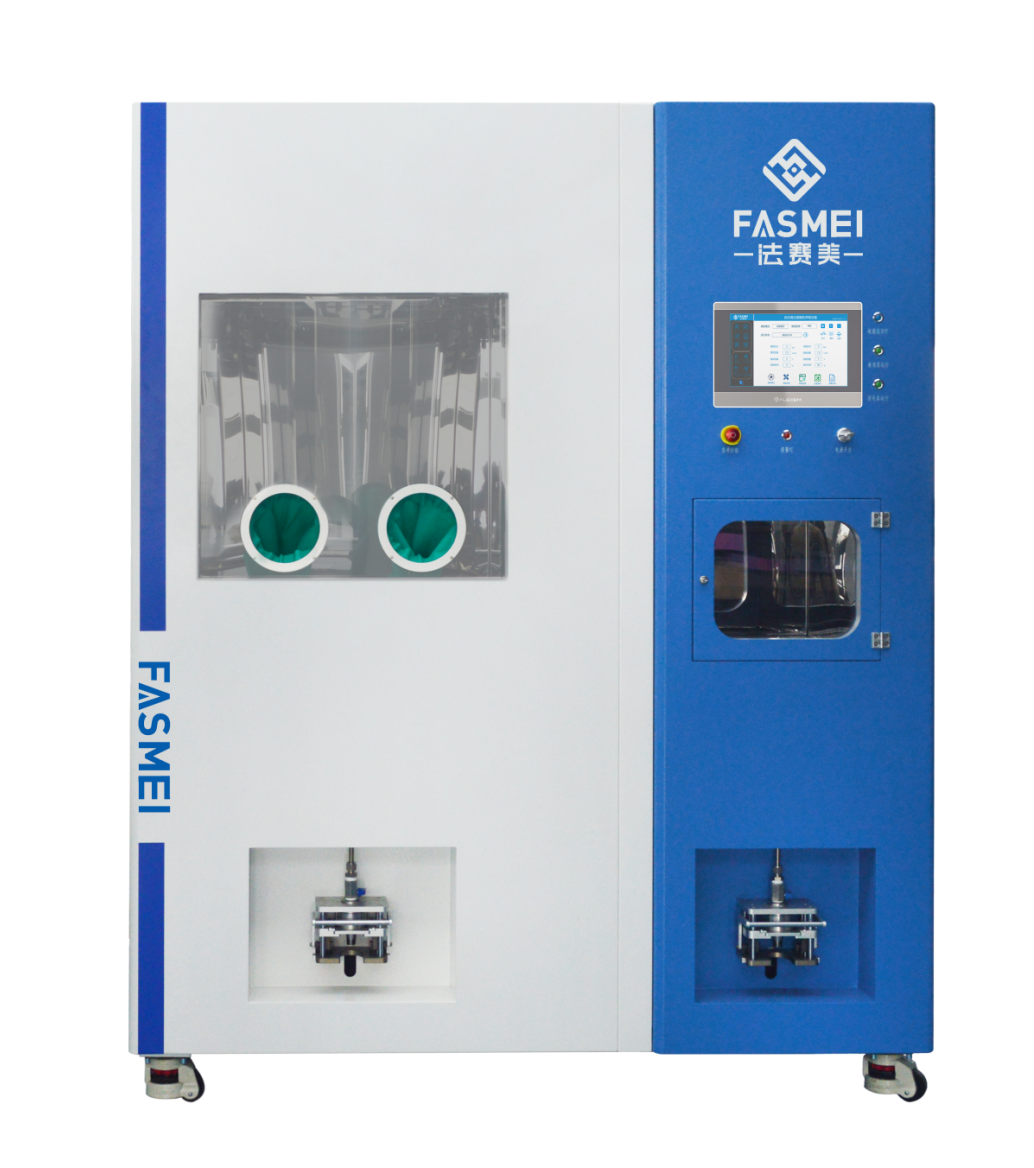

FASMEI Cleanliness extraction equipment: spray washing, ultrasonic, perfusion, dry particle suction extraction equipment

FASMEI Cleanliness extraction device introduction

FASMEI has a complete product line of clean particle extraction, both dry and wet.

Dry extraction advantages:

Using dry air to extract particles can realize non-disassembly and non-destructive cleanliness detection of parts;

When inspecting large parts, it saves more time and logistics costs than the "wet method";

With high functional integration and mobility, real-time on-site inspection of parts and working environment can be carried out.

After extraction, the particles on the filter paper can be directly evaluated in real time.

Fast extraction of particulate matter to avoid long-term interruption of the production process;

The separation control area can be accurately tested without any additional means, such as covering.

Can provide heavy parts cleaning design;

Large flow internal flushing detection scheme;

It can provide automatic cleaning extraction equipment for the cleanliness test of parts with different sizes and indexes.

FASMEI has a complete product line of clean particle extraction, both dry and wet.

Dry extraction advantages:

Using dry air to extract particles can realize non-disassembly and non-destructive cleanliness detection of parts;

When inspecting large parts, it saves more time and logistics costs than the "wet method";

With high functional integration and mobility, real-time on-site inspection of parts and working environment can be carried out.

After extraction, the particles on the filter paper can be directly evaluated in real time.

Fast extraction of particulate matter to avoid long-term interruption of the production process;

The separation control area can be accurately tested without any additional means, such as covering.

FASMEI can provide a full range of wet extraction solutions, such as spray cleaning, ultrasonic cleaning, perfusion washing, shaking cleaning solutions;

Different cleaning solvent extraction equipment design scheme;Can provide heavy parts cleaning design;

Large flow internal flushing detection scheme;

It can provide automatic cleaning extraction equipment for the cleanliness test of parts with different sizes and indexes.

Automatic cleanliness extraction equipment - wet process

Wet cleaning particle extraction is widely used, can be used in most parts cleaning detection, according to different parts cleaning methods can be divided into spray cleaning [pressure and flow rate two modes], ultrasonic cleaning, perfusion cleaning, air purging, shaking test, etc.

Necessary blank test and decline test

How to choose the test method?

Cleaning solvent selection compatibility issues?

Filter aperture selection?

How to select heavy parts cleanliness extraction equipment?

Particle index [size and quantity] High cleanliness cleaning machine How to select?

Which effective solution is preferred for washing the inside surface of the product?

Please contact your sales representative for specific options.

Necessary blank test and decline test

How to choose the test method?

Cleaning solvent selection compatibility issues?

Filter aperture selection?

How to select heavy parts cleanliness extraction equipment?

Particle index [size and quantity] High cleanliness cleaning machine How to select?

Which effective solution is preferred for washing the inside surface of the product?

Please contact your sales representative for specific options.

Particle suction extraction system - dry method

The new mobile particle extraction system collects pollution particles by suction extraction,

Thus, a new dynamic non-destructive particle collection and detection method is established.

This makes technical cleanliness testing for large, high-surface parts and work site environments more efficient, economical, accurate and industry-specific.

In contrast to so-called "wet" flushing particulate collection methods (such as liquid medium extraction described in VDA 19.1 or ISO 16232),

This innovative "dry" particle extraction method has unique and irreplaceable advantages in a variety of applications.

Contact your sales representative for ESD versions

Thus, a new dynamic non-destructive particle collection and detection method is established.

This makes technical cleanliness testing for large, high-surface parts and work site environments more efficient, economical, accurate and industry-specific.

In contrast to so-called "wet" flushing particulate collection methods (such as liquid medium extraction described in VDA 19.1 or ISO 16232),

This innovative "dry" particle extraction method has unique and irreplaceable advantages in a variety of applications.

Contact your sales representative for ESD versions

Other accessories

Clean hood

SUS304 Storage tank

Pressure gun

Positive and negative pressure pump

Filter membrane filtration System

Flow Monitoring System

Small ultrasonic cleaning machine

Hydrocarbon solvent: AP760/HAKU1025/D60 series

Precision filter

Drying dish

Weighing dish

Stainless steel tweezers

Dust-free cloth

Ding Qing gloves

SUS304 Storage tank

Pressure gun

Positive and negative pressure pump

Filter membrane filtration System

Flow Monitoring System

Small ultrasonic cleaning machine

Hydrocarbon solvent: AP760/HAKU1025/D60 series

Precision filter

Drying dish

Weighing dish

Stainless steel tweezers

Dust-free cloth

Ding Qing gloves