FASMEI Cleanliness Inspection Solutions - Many solutions to choose from

Cleanliness solutions expert——FASMEI

FASMEI has a full range of parts cleanliness testing products with independent intellectual property rights, and is the most complete manufacturer of cleanliness equipment suppliers, including intelligent cleanliness analysis system, lithium electromagnetic particle testing system, lithium electromagnetic particle sample preparation equipment, automatic cleanliness extraction equipment, dry particle suction extraction system, filter membrane rapid drying machine.

FASMEI cleanliness testing equipment fully meets international cleanliness testing standards such as ISO16232/VDA19.

We have a wealth of cleanliness solution capabilities to provide proven and reliable cleanliness solutions for different types of customers.

FSMEI not only provides cleanliness testing equipment, but also provides customers with standard cleanliness clean room design and construction capabilities, which meet the ISO14644/VDA19.2 standard specification

FASMEI can provide customers in the automotive and new energy industries with a variety of high quality cleanliness consumables and accessories.

FASMEI has a full range of parts cleanliness testing products with independent intellectual property rights, and is the most complete manufacturer of cleanliness equipment suppliers, including intelligent cleanliness analysis system, lithium electromagnetic particle testing system, lithium electromagnetic particle sample preparation equipment, automatic cleanliness extraction equipment, dry particle suction extraction system, filter membrane rapid drying machine.

FASMEI cleanliness testing equipment fully meets international cleanliness testing standards such as ISO16232/VDA19.

We have a wealth of cleanliness solution capabilities to provide proven and reliable cleanliness solutions for different types of customers.

FSMEI not only provides cleanliness testing equipment, but also provides customers with standard cleanliness clean room design and construction capabilities, which meet the ISO14644/VDA19.2 standard specification

FASMEI can provide customers in the automotive and new energy industries with a variety of high quality cleanliness consumables and accessories.

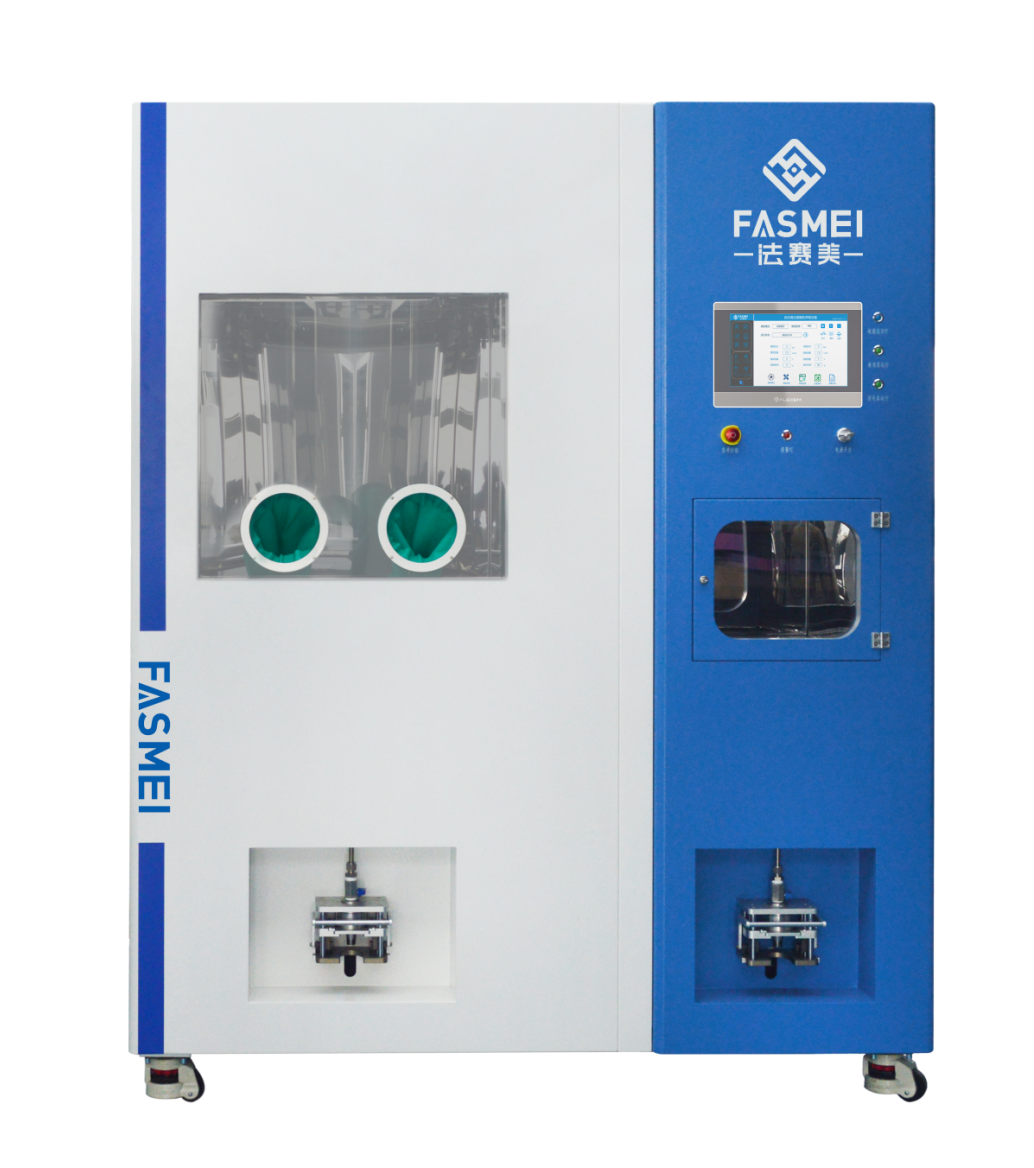

Dry particle extraction

Using dry air to extract particles can realize non-disassembly and non-destructive cleanliness detection of parts;

Parts or raw materials that cannot be tested by "wet method";

With high functional integration and mobility, real-time on-site inspection of parts and working environment can be carried out.

Application:

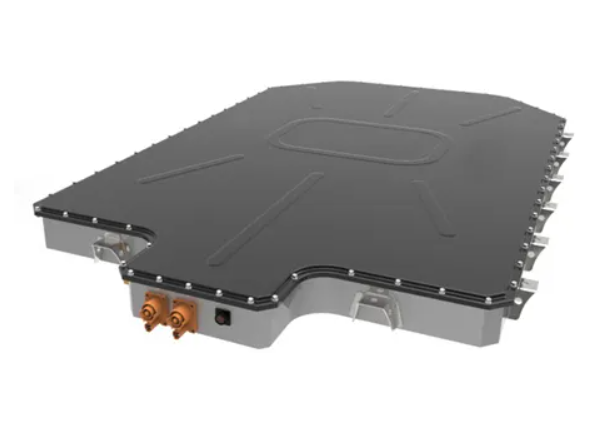

Battery

Module

Battery pack

Electronic components

Motor stator

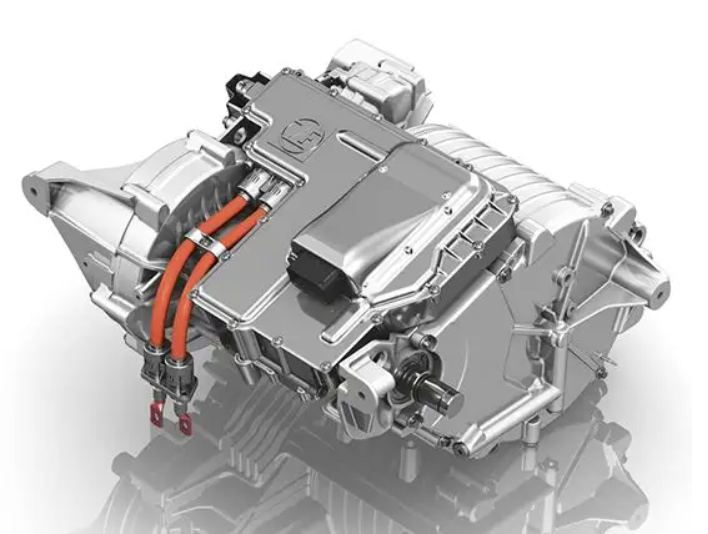

Electric drive assembly

Parts or raw materials that cannot be tested by "wet method";

With high functional integration and mobility, real-time on-site inspection of parts and working environment can be carried out.

Application:

Battery

Module

Battery pack

Electronic components

Motor stator

Electric drive assembly

High flow irrigation scheme

How can products with a certain volume cavity be more efficient for particle extraction?

Applied to internal flushing to form RE≥4000 turbulent flushing

Flow rate range: 1-60L/MIN irrigation scheme optional

Optional pulse cleaning, electric shaking, vibration cleaning

Application:

Radiator

Intercooler

Condenser

Evaporator

Pump valve

Battery cooler

Applied to internal flushing to form RE≥4000 turbulent flushing

Flow rate range: 1-60L/MIN irrigation scheme optional

Optional pulse cleaning, electric shaking, vibration cleaning

Application:

Radiator

Intercooler

Condenser

Evaporator

Pump valve

Battery cooler

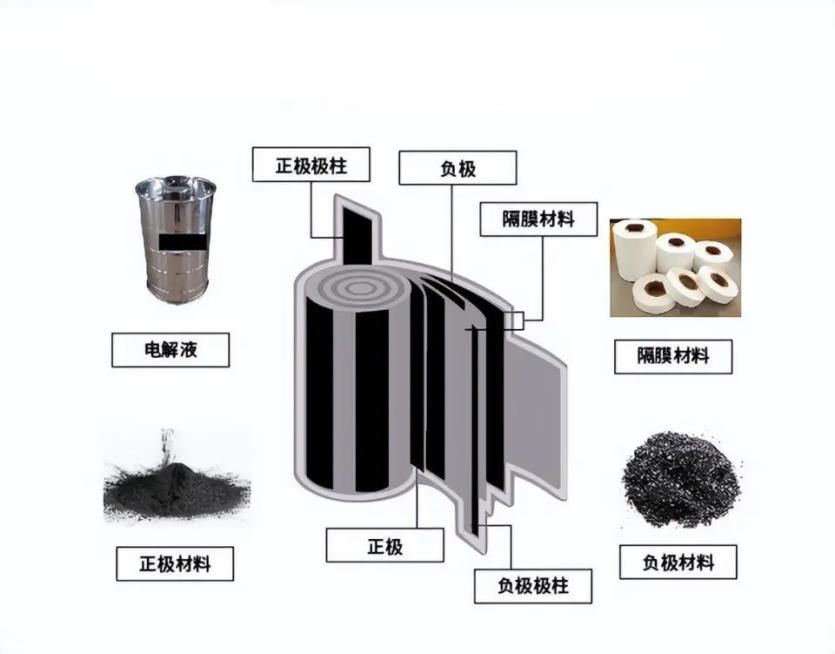

Extraction and analysis of magnetic particles in lithium battery raw materials

Magnetic particles will affect the stability, durability and cycle life of the battery

In the production process of lithium batteries, metal particle control is particularly important.

Application:

Positive and negative electrode materials

Slurry

Separator

Electrolyte

Various additives

Aluminum foil and copper foil

In the production process of lithium batteries, metal particle control is particularly important.

Application:

Positive and negative electrode materials

Slurry

Separator

Electrolyte

Various additives

Aluminum foil and copper foil